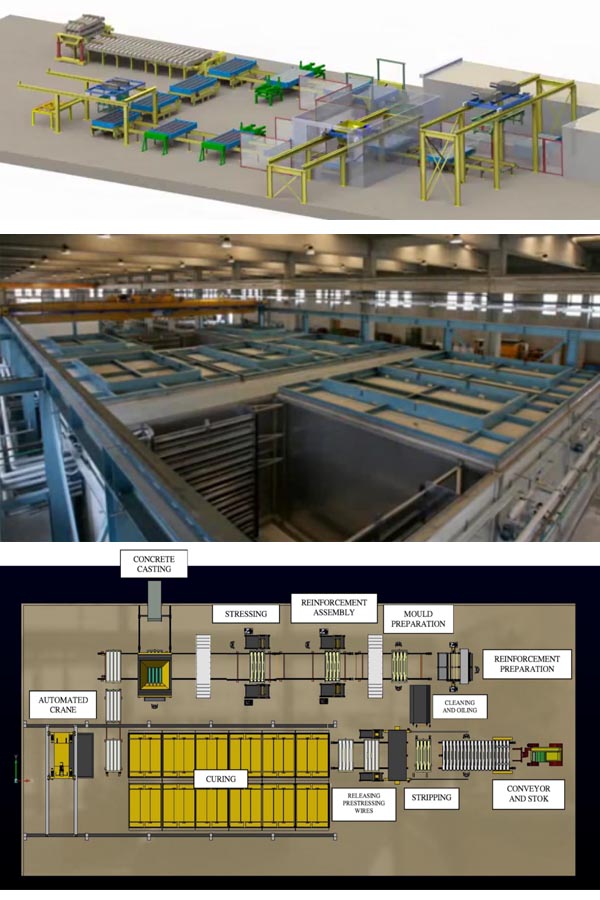

Prestressed Concrete Mainline Sleepers Production Plants

The Karousel Method Sleeper Production is a method that enables production that could go on for 24 hours through a circular loop.

Production is made with the help of sleepers moulds and each production mould has 4 traverse production compartments. Through the plaques located on the molds the sleeper type, its mould number, its production date, from which section the mold was produced and for whom it was produced can be monitored and this allows the long-term traceability of the sleepers.

These 4 sections process stretching through production assisting equipments such as prestressing reinforcement, stressing plates, bolts and tie-rods, nuts and tie-rods. Each sleepers is applied stressing related to the railway axle and project cargo

After the stressing procedure is completed, the production molds manufactured by the conveyor are led to the concrete casting section. When the sleeper moulds are ready for production, the production operator can use the communication system on the command panel to request concrete. The concrete is poured into the sleeper mould in 3-4 stages within 1-1,5 minutes and thin 2-staged vibration is applied on the mould.

After the concrete casting procedure is completed the moulds are turned into a vapor cure that automatically opens and closes. The temperature in the vapor halls are recorded through a digital and printing system. Also, the inner temperature is identified by an electronic measuring device. Once the system identifies that the pressure resistance for a 150 mm2 cube sample sleeper subjected to the vapor cure is min. 45 N/mm2, prestressed steel reinforcements are transferred to the concrete. The sleepers, which are taken out from the mould through and automated system, are put on a carrying line. After their date of production is inscribed, they are sent to the temporary stock line and then to the stock field. The machines used during production can be turned to full automatic or semi-automatic.

Machines and Molds Used in The Karousel Mainline Traverse Production Facility;

- PRODUCTİON MOULDS

- REİNFORCEMENT PREPARATİON MACHİNE

- PRESTRESSING MACHINE

- STRESSING MACHINE

- CONCRETE CASTİNG MACHINE

- AUTOMATED CURING CRANE

- CURİNG ROOMS

- CURE MACHİNE AND CONNECTİON PİPES

- RELEASING PRESTRESSING WIRES

- STRIPPING

- MOULD CLEANING AND OILING MACHINE

- CONVEYOR

- STOCKİNG MACHİNE

LABORATORY

An laboratory within the facility's 100-150 m2 indoor area or in an adjacent building is necessary in order to check whether the sleeper quality is

fitting to the TS EN 13230 standards and in order to make R&D studies when the need arises. The personnel working in the facility need to be familiar

with the EN 13230 quality standards and they also need to be experts on concrete. Aggregate, cement, water, concrete chemicals and prestressed

rod sample tests also need to be done at certain time intervals in this laboratory.

Sleeper Test Equipment Used in the Laboratory

- A Static Test Press is one of the most important test equipments. Force is applied statically at certain intervals specified in the EN 13230 standards on the Sleeper Ray Aging Surface in order to check for fractures.

- Sleeper Rail Seating Surface Shoulder Width Measurement Device

- Sleeper Rail Seating Between-Surfaces Measurement Device

- Sleeper Rail Seating Surface Inclination And Torsion Measurement Device