Prefabricated Concrete Element Production Plants

Prefabricated concrete elements are nowadays used in almost all areas of life. In developed and industrialized countries,prefabricated concrete construction elements are commonly used in building and railway construction projects. There are manyadvantages in using prefabricated concrete constructions during a project. These advantages are in short: the reduction of totalproduction costs, faster completion of a project, the maintenance of quality and enduring construction elements, the reduction of materialwaste, increase in moduleration and standardization possibilities and a serious reduction in possible work accidence that could occur inthe worksite.

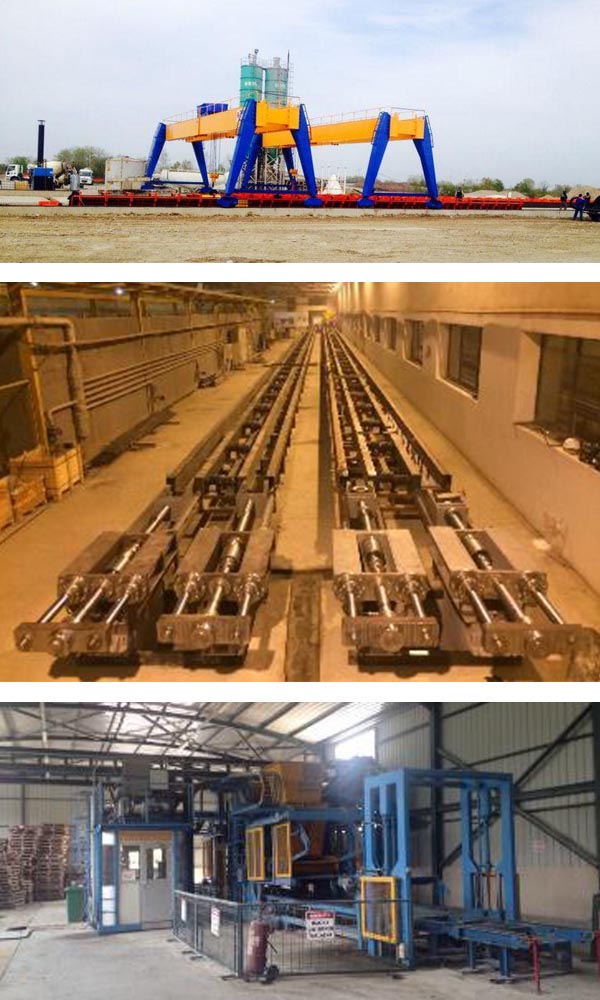

Our company produces and completes many turnkey projects, especially in prestressed concrete. The areas of activity of ourcompany are as following:

- Prestressed Concrete Outline Traverse Production Facilities

- Prestressed Concrete Bridge Beams Production Facilities

- Concrete Cable Channels, Flooring and Concrete Paving Production Facilities

- Concrete Pucker Pipe Production Facilities

- Concrete road barriers Production Facilities

- Beton Yol bariyeri Üretim Tesisi

- Concrete road barriers Production Facilities

- Concrete Electric Pole Production

All turnkey projects completed by our company are carried out in collaboration with business owners in all steps of the project,including pre-production, during production and post-production. Through this act of disclosure and cooperation, business owners will beable to do their planning on strong foundations and thus possible future location-based problems can be prevented. Furthermore, theproduction will be examined in certain periods of time after the project is completed, in order to maintain quality, showing that ourcompany is beihnd its work all the way.

Our pre-project activities are as following:

- We complete feasibility studies on the area where the site will be built

- We prepare the infrastructure, superstructure and master plans necessary for the installation of the production site, as well asthe cost analysis

- During the production site installation process following preparations are done about concrete

-The analysis of crushing and screening facilities near the production site for the aggregates used for the concrete (its distanceto the building site, price and quality comparisons, laboratory tests)

- The analysis of the cement used for the concrete and pre-trial in laboratory environment (where the cement should beacquired from, the analysis of quality documents etc)

- The water used for the concrete should also be tested.

- We analyze and report the technical conditions and standards of the prefabricated elements according to their field of use(railways, highways etc)

- We decide the organizational scheme and decide on the number of personnel in the production site and their responsibilitycharts

- Tesiste görev alacak personelin sayısı görev ve sorumluluk çizelgeleri ve organizasyon şemasının hazırlanması

- We prepare the quality control documents and laboratory test documents to be used in production

- We organize and deliver all necessary reporting documents for the production